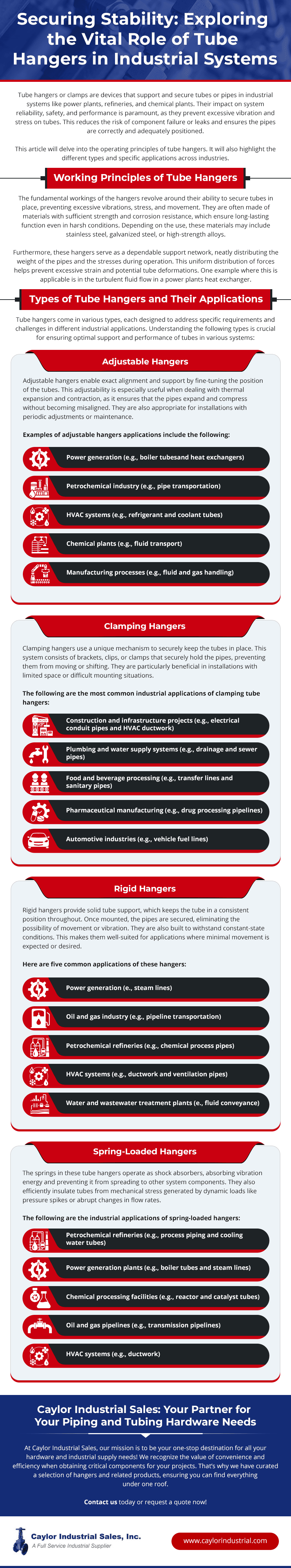

Tube hangers or clamps are devices that support and secure tubes or pipes in industrial systems like power plants, refineries, and chemical plants. Their impact on system reliability, safety, and performance is paramount, as they prevent excessive vibration and stress on tubes. This reduces the risk of component failure or leaks and ensures the pipes are correctly and adequately positioned.

This article will delve into the operating principles of tube hangers. It will also highlight the different types and specific applications across industries.

Working Principles of Tube Hangers

The fundamental workings of the hangers revolve around their ability to secure tubes in place, preventing excessive vibrations, stress, and movement. They are often made of materials with sufficient strength and corrosion resistance, which ensure long-lasting function even in harsh conditions. Depending on the use, these materials may include stainless steel, galvanized steel, or high-strength alloys.

Furthermore, these hangers serve as a dependable support network, neatly distributing the weight of the pipes and the stresses during operation. This uniform distribution of forces helps prevent excessive strain and potential tube deformations. One example where this is applicable is in the turbulent fluid flow in a power plants heat exchanger.

Types of Tube Hangers and Their Applications

Tube hangers come in various types, each designed to address specific requirements and challenges in different industrial applications. Understanding the following types is crucial for ensuring optimal support and performance of tubes in various systems:

Adjustable Hangers

Adjustable hangers enable exact alignment and support by fine-tuning the position of the tubes. This adjustability is especially useful when dealing with thermal expansion and contraction, as it ensures that the pipes expand and compress without becoming misaligned. They are also appropriate for installations with periodic adjustments or maintenance.

Examples of adjustable hangers applications include the following:

- Power generation (e.g., boiler tubesand heat exchangers)

- Petrochemical industry (e.g., pipe transportation)

- HVAC systems (e.g., refrigerant and coolant tubes)

- Chemical plants (e.g., fluid transport)

- Manufacturing processes (e.g., fluid and gas handling)

Clamping Hangers

Clamping hangers use a unique mechanism to securely keep the tubes in place. This system consists of brackets, clips, or clamps that securely hold the pipes, preventing them from moving or shifting. They are particularly beneficial in installations with limited space or difficult mounting situations.

The following are the most common industrial applications of clamping tube hangers:

- Construction and infrastructure projects (e.g., electrical conduit pipes and HVAC ductwork)

- Plumbing and water supply systems (e.g., drainage and sewer pipes)

- Food and beverage processing (e.g., transfer lines and sanitary pipes)

- Pharmaceutical manufacturing (e.g., drug processing pipelines)

- Automotive industries (e.g., vehicle fuel lines)

Rigid Hangers

Rigid hangers provide solid tube support, which keeps the tube in a consistent position throughout. Once mounted, the pipes are secured, eliminating the possibility of movement or vibration. They are also built to withstand constant-state conditions. This makes them well-suited for applications where minimal movement is expected or desired.

Here are five common applications of these hangers:

- Power generation (e., steam lines)

- Oil and gas industry (e.g., pipeline transportation)

- Petrochemical refineries (e.g., chemical process pipes)

- HVAC systems (e.g., ductwork and ventilation pipes)

- Water and wastewater treatment plants (e., fluid conveyance)

Spring-Loaded Hangers

The springs in these tube hangers operate as shock absorbers, absorbing vibration energy and preventing it from spreading to other system components. They also efficiently insulate tubes from mechanical stress generated by dynamic loads like pressure spikes or abrupt changes in flow rates.

The following are the industrial applications of spring-loaded hangers:

- Petrochemical refineries (e.g., process piping and cooling water tubes)

- Power generation plants (e.g., boiler tubes and steam lines)

- Chemical processing facilities (e.g., reactor and catalyst tubes)

- Oil and gas pipelines (e.g., transmission pipelines)

- HVAC systems (e.g., ductwork)

Caylor Industrial Sales: Your Partner for Your Piping and Tubing Hardware Needs

At Caylor Industrial Sales, our mission is to be your one-stop destination for all your hardware and industrial supply needs! We recognize the value of convenience and efficiency when obtaining critical components for your projects. That’s why we have curated a selection of hangers and related products, ensuring you can find everything under one roof.

Contact us today or request a quote now!