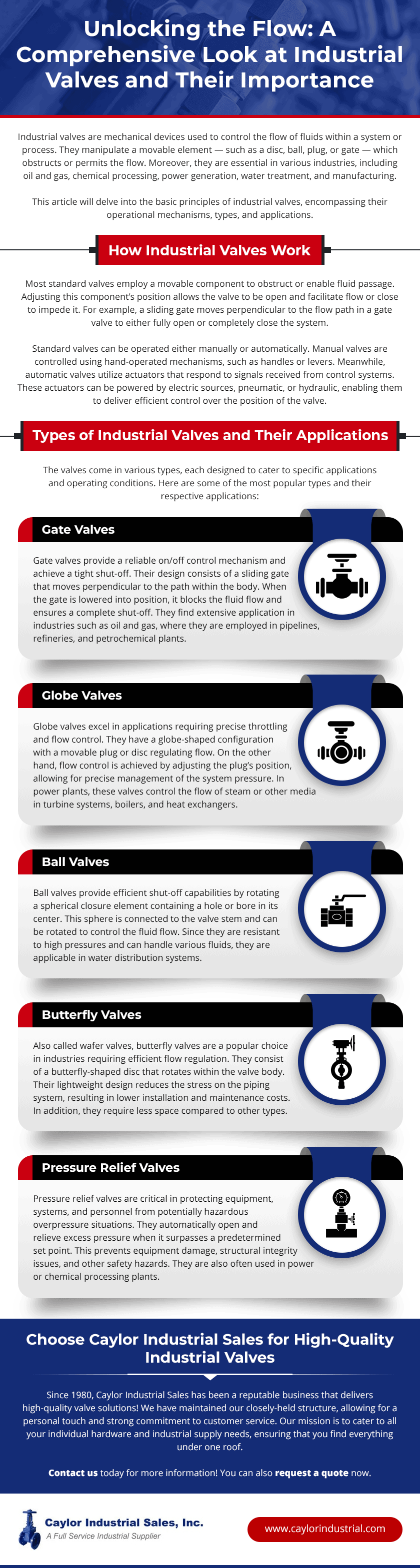

Industrial valves are mechanical devices used to control the flow of fluids within a system or process. They manipulate a movable element — such as a disc, ball, plug, or gate — which obstructs or permits the flow. Moreover, they are essential in various industries, including oil and gas, chemical processing, power generation, water treatment, and manufacturing.

This article will delve into the basic principles of industrial valves, encompassing their operational mechanisms, types, and applications.

How Industrial Valves Work

Most standard valves employ a movable component to obstruct or enable fluid passage. Adjusting this component’s position allows the valve to be open and facilitate flow or close to impede it. For example, a sliding gate moves perpendicular to the flow path in a gate valve to either fully open or completely close the system.

Standard valves can be operated either manually or automatically. Manual valves are controlled using hand-operated mechanisms, such as handles or levers. Meanwhile, automatic valves utilize actuators that respond to signals received from control systems. These actuators can be powered by electric sources, pneumatic, or hydraulic, enabling them to deliver efficient control over the position of the valve.

Types of Industrial Valves and Their Applications

The valves come in various types, each designed to cater to specific applications and operating conditions. Here are some of the most popular types and their respective applications:

Gate Valves

Gate valves provide a reliable on/off control mechanism and achieve a tight shut-off. Their design consists of a sliding gate that moves perpendicular to the path within the body. When the gate is lowered into position, it blocks the fluid flow and ensures a complete shut-off. They find extensive application in industries such as oil and gas, where they are employed in pipelines, refineries, and petrochemical plants.

Globe Valves

Globe valves excel in applications requiring precise throttling and flow control. They have a globe-shaped configuration with a movable plug or disc regulating flow. On the other hand, flow control is achieved by adjusting the plug’s position, allowing for precise management of the system pressure. In power plants, these valves control the flow of steam or other media in turbine systems, boilers, and heat exchangers.

Ball Valves

Ball valves provide efficient shut-off capabilities by rotating a spherical closure element containing a hole or bore in its center. This sphere is connected to the valve stem and can be rotated to control the fluid flow. Since they are resistant to high pressures and can handle various fluids, they are applicable in water distribution systems.

Butterfly Valves

Also called wafer valves, butterfly valves are a popular choice in industries requiring efficient flow regulation. They consist of a butterfly-shaped disc that rotates within the valve body. Their lightweight design reduces the stress on the piping system, resulting in lower installation and maintenance costs. In addition, they require less space compared to other types.

Pressure Relief Valves

Pressure relief valves are critical in protecting equipment, systems, and personnel from potentially hazardous overpressure situations. They automatically open and relieve excess pressure when it surpasses a predetermined set point. This prevents equipment damage, structural integrity issues, and other safety hazards. They are also often used in power or chemical processing plants.

Choose Caylor Industrial Sales for High-Quality Industrial Valves

Since 1980, Caylor Industrial Sales has been a reputable business that delivers high-quality valve solutions! We have maintained our closely-held structure, allowing for a personal touch and strong commitment to customer service. Our mission is to cater to all your individual hardware and industrial supply needs, ensuring that you find everything under one roof.

Contact us today for more information! You can also request a quote now.